•Gearhead and Intermediate gearhead are sold separately.

•Enter the reduction ratio into the blank(□) within the model name.

•The speed is calculated by dividing the motor's synchronous speed by the reduction ratio. The actual speed is 2%~20% less than the displayed value, depending on the size of the load.

•To reduce the speed beyond the reduction ratio in the following table, attach an intermediate gearhead (reduction ratio: 10) between the reducer and motor. In that case, the permissible torque is 8N-m.

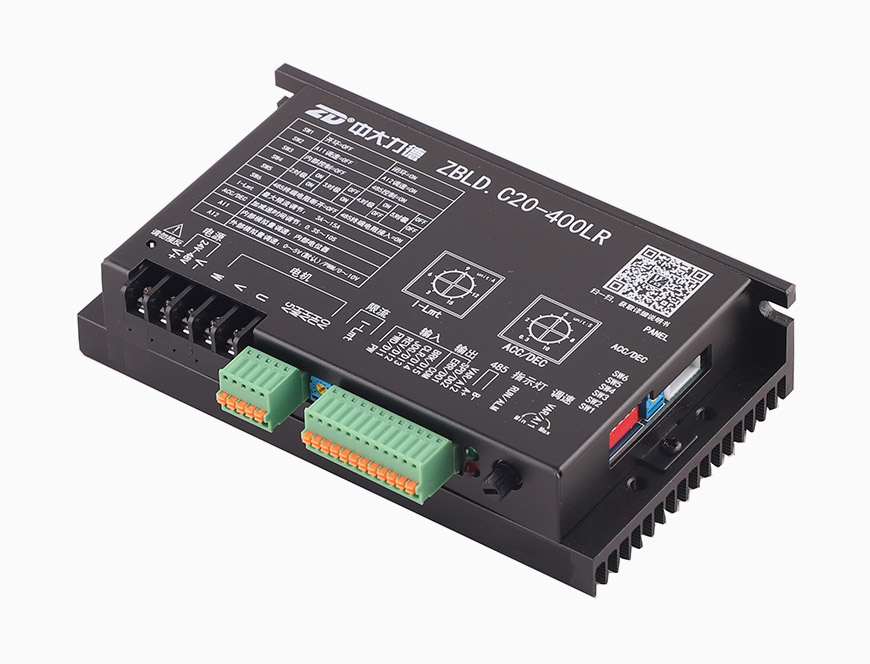

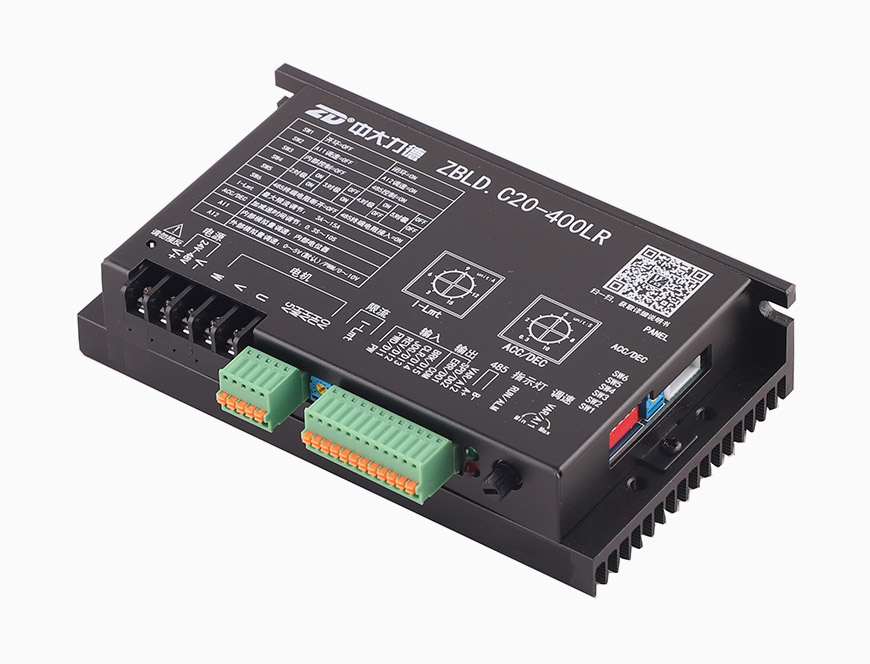

ZBLD.C20-400LR Low Voltage DC 400W Brushless Motor Driver Controller

Feature:

1、Digital panel display speed, error code and other information

2、Panel knob stepless speed regulation (0~3000rpm)

3、Accuracy of steady speed ±0.5%

4、External terminal switching reverse rotation (external connection NPN PLC)

5、Speed pulse output function (SPD = 20*f/p, f is the frequency of output pulse, p is the brushless motor pole logarithm)

6、Standard motor interface, can be directly inserted with the motor terminal

7、Support extended functionality (extended IO, external analog volume, 485 communication). -- this function needs special, plus an expansion board